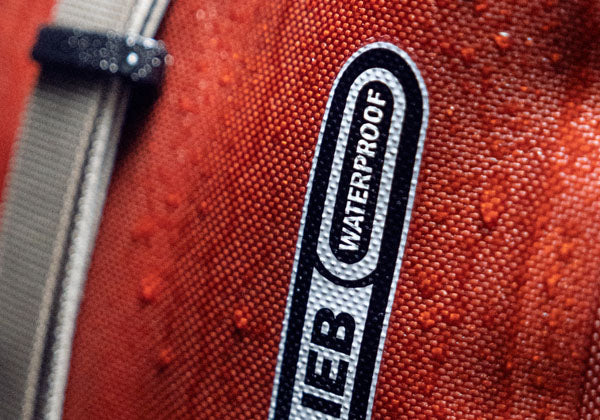

Waterproof

ORTLIEB's waterproof quality is based on manufacturing in Germany using high-quality, durable materials and robust connections. For maximum waterproofing, the seams are processed using a high-frequency welding process, which enables permanently tight connections without adhesives. The products are tested for waterproofing according to recognized IP standards.

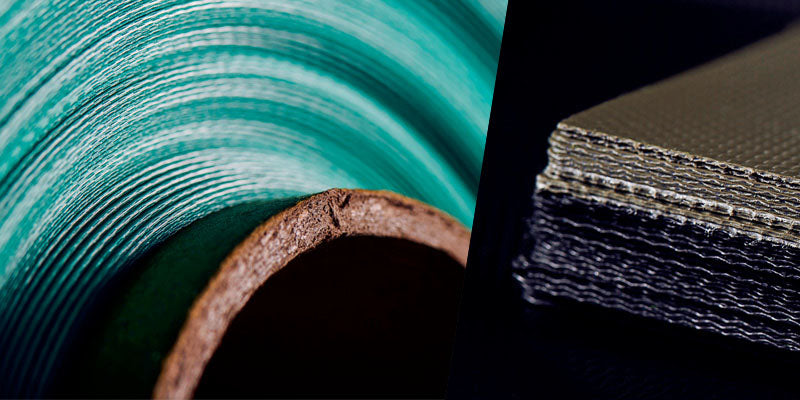

Durable Materials

Our outstanding waterproof quality is based on selected materials that are developed for specific applications. Such materials include polyester, nylon and Cordura fabrics that are coated on one or both sides. If a fabric is coated on one side only, the opposite side will retain its textile look. If both sides of a fabric are coated, they will both have the familiar tarpaulin look. ORTLIEB's thermoplastic coatings meet extremely high waterproofing specifications, and are therefore far superior to most commercially available tent or backpack coatings.

Advanced Bonding Methods

The coated fabric used by ORTLIEB – including all welded seams – continues to resist leaking when exposed to a 100,000 mm column of water! This extreme degree of waterproofing is achieved using a process known as high frequency welding (HFW). Instead of applying heat from the outside, HFW involves the application of high frequency voltage to the objects that need to be welded. The voltage causes the molecules within the various materials to vibrate and, essentially, to generate heat. Softened from within by the heat, the materials are then bonded under high pressure, leaving the welded seam at least as strong as the surrounding material.

Proven closures

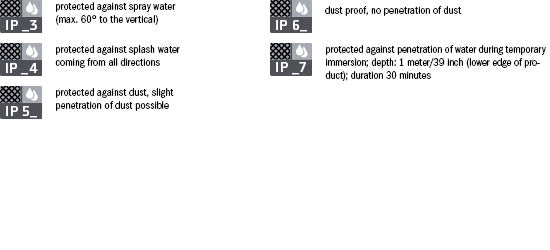

The third important factor for high waterproof and dustproof performance is the type of closures used. All of the closures used in ORTLIEB products are subjected to extensive environmental simulation testing. One common test parameter is referred to as ingress protection (IP). Originally used in the field of electrical engineering, IP ratings have become increasingly common in the outdoor recreation sector.

Flap closure

Flap closures protect against dust and spray water from angles of up to 60° to 90°. Also available with a snow shield or an additional roll closure, the flap accomplishes its mission on every outing. Snap buckles and hooks are used to secure the flap’s closure. Products in the City Line are typically outfitted with magnetic fasteners to facilitate handling.

Roll closure

The roll closure is a simple, effective and highly versatile means of keeping the inside separate from the outside. It is completely dustproof and protects the pages-columns of ORTLIEB bags against spray water from all directions. The roll closure gains its stability and waterproof quality from the thin plastic stiffener bars sewn into the upper end of the material. The height or volume of packed bags can also be reduced by rolling up the material further. Those interested in maximum compactness are encouraged to select the model with the integrated valve.

Quick-Seal-Closure

The Quick Seal Closure allows you to quickly open and close your ORTLIEB bag by simply moving a slider along two flexible plastic profiles. The closure reliably protects the inside of the bag against dust and spray water from all directions. Ideal for daily use!

Advice: The Quick Seal closure may not work properly at temperatures of less than -5°C/23°F.

Waterproof zipper

TIZIP zippers reliably prevent water and dust from entering your ORTLIEB bags. The inside of the bags will remain dry when submerged under 1 meter of water for a period of 30 minutes. The waterproof and dustproof design leads to a slightly greater degree of friction when opening and closing the bag.

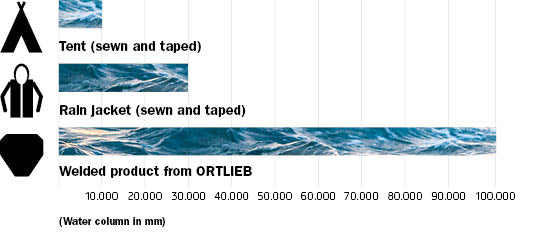

Waterproof Ratings: What’s Behind the Numbers?

A standard procedure (ISO 811) is commonly used to determine the degree to which a material or fabric is waterproof. Sometimes referred to as the hydrostatic head test, the procedure determines the pressure – measured by the height in millimeters of a column of water held in a tube above the fabric – at which the fabric begins to leak. A piece of fabric that shows no signs of leaking when placed under a 4,000 mm column of water is essentially capable of withstanding the hydrostatic pressure objects are exposed to at a submerged depth of four meters.

The hydrostatic head: ORTLIEB vs. other waterproof products

The IP protection classes of ORTLIEB bags